GROWING THE GOODNESS

Bringing Game-Changing Innovation to Ag Industry

The rise of innovative technology in agriculture is revolutionizing the farming practices of almond growers. Blue Diamond

grower and Young Leader Gary Thompson is helping to bring growers this game-changing technology designed to make

their lives better. Recently relocating from Arizona to California, Gary works as marketing director for the world’s first and

only autonomous orchard sprayer, and is responsible for the

machine’s website, social media pages, marketing videos,

news interviews, and advertisements.

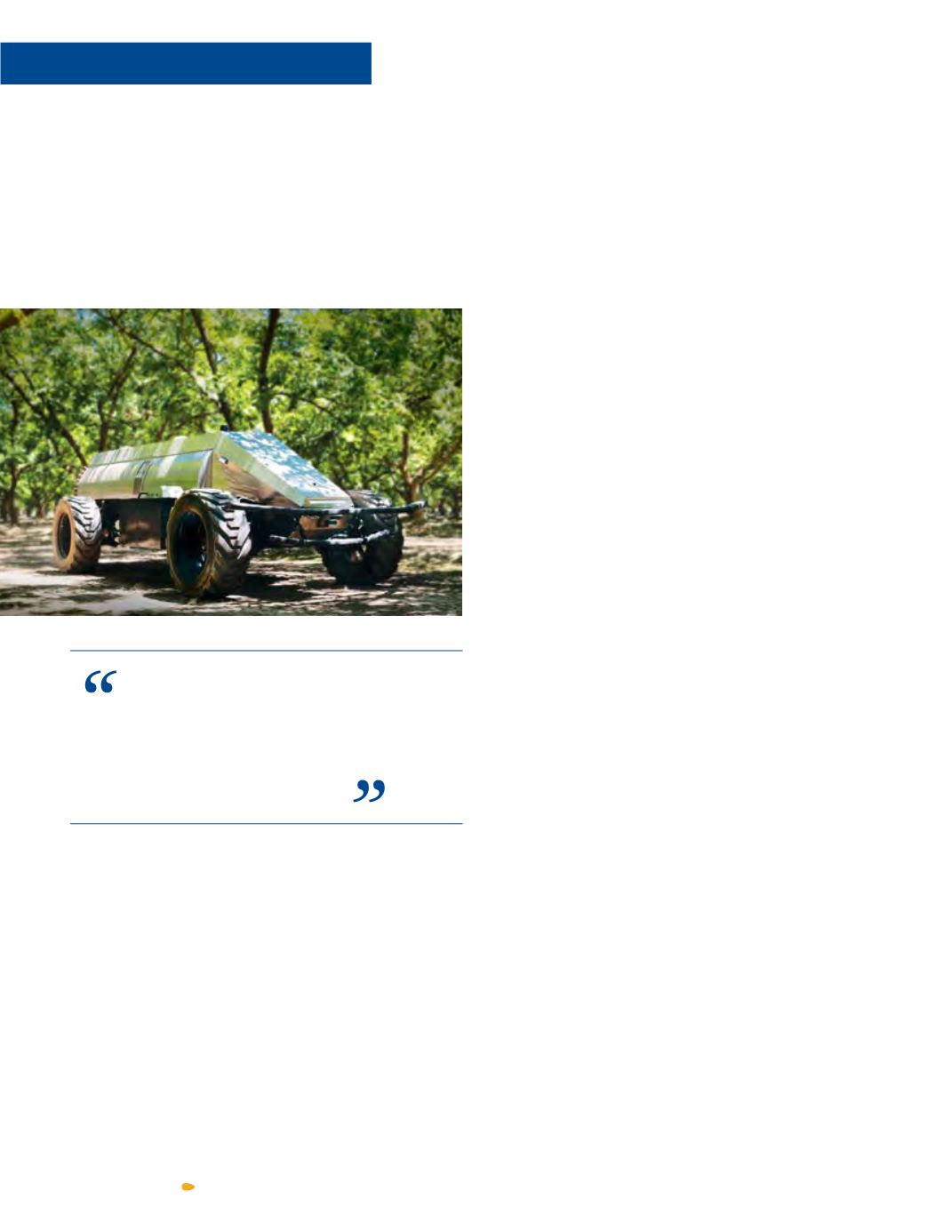

Meet GUSS, the Global Unmanned Spray System. Gary

acknowledges that GUSS came about out of necessity

and the sprayer’s roots can be traced all the way back

to 1982 when its innovative founder Dave Crinklaw

and father Bob started an agriculture spray business

called Crinklaw Farm Services. Inc., known today as

CFS LP. Beginning with just two sprayers, driven by Dave

and Bob, they averaged about 40 acres a day. After

developing the industry’s first three and four-row vineyard

sprayers, mechanical vineyard pruners, and the Tree-

See orchard sprayer, CFS LP now sprays an average of

5,000 acres a day during peak season.

“When we started experiencing a shortage of labor

necessary to drive our sprayers and had substantial

increases in labor costs, it became apparent to us that

we needed to adapt and change in order to thrive in this

difficult business environment,” explained Gary.

It wasn’t until 2014 that Dave Crinklaw decided technology

was advanced enough to begin developing the concept

of GUSS. Gary admits that the autonomous sprayer, designed to drive itself in a very safe and precise matter, went

through more than three and a half years of development and testing before it was deemed ready for action.

“The obvious benefit of GUSS is the labor efficiency,” noted Gary.

Here’s how GUSS works. The autonomous sprayer moves continuously through the orchard, stopping only to be refilled.

Vehicle speed, fan speed and application rates are set precisely into GUSS’ software and remain consistent across the

entire field. GUSS is equipped with a camera which live streams video to a control van operator.

“We are seeing big improvements in efficiency, accuracy, and safety with GUSS,” said Gary. “GUSS has less down time

The ability to run 10 machines

monitored by one person will help

solve a lot of the labor challenges

faced by growers.

2 6

A L M O N D F A C T S