MARCH | APRIL 2016

Almond Facts

11

Specific improvement projects that

were highlighted included:

• Food safety enhancements

made to the continuous cookers,

including upgrading the conveyor

in-feed belts and oil filtration

systems. These cookers are most

commonly used to produce

oil-roasted almonds such as

Smokehouse, Low Sodium,

Roasted Salted, Wasabi & Soy

and Honey Roast.

• Food safety enhancements to the

small particle roaster, including

upgrades to the in-feed system,

filtration system and renovated

centrifuges to improve performance.

This equipment is used for such

Global Ingredient products as

roasted blanched almond slivers

and roasted diced almonds.

• New electronic sorting equipment

for the removal of foreign

material and improve overall

quality is currently being tested

to replace existing technologies.

• Sprint team work on the Butter

Mill and Vend Pack lines that

increased throughput, and

delivered margin enhancements

with minimal investment.

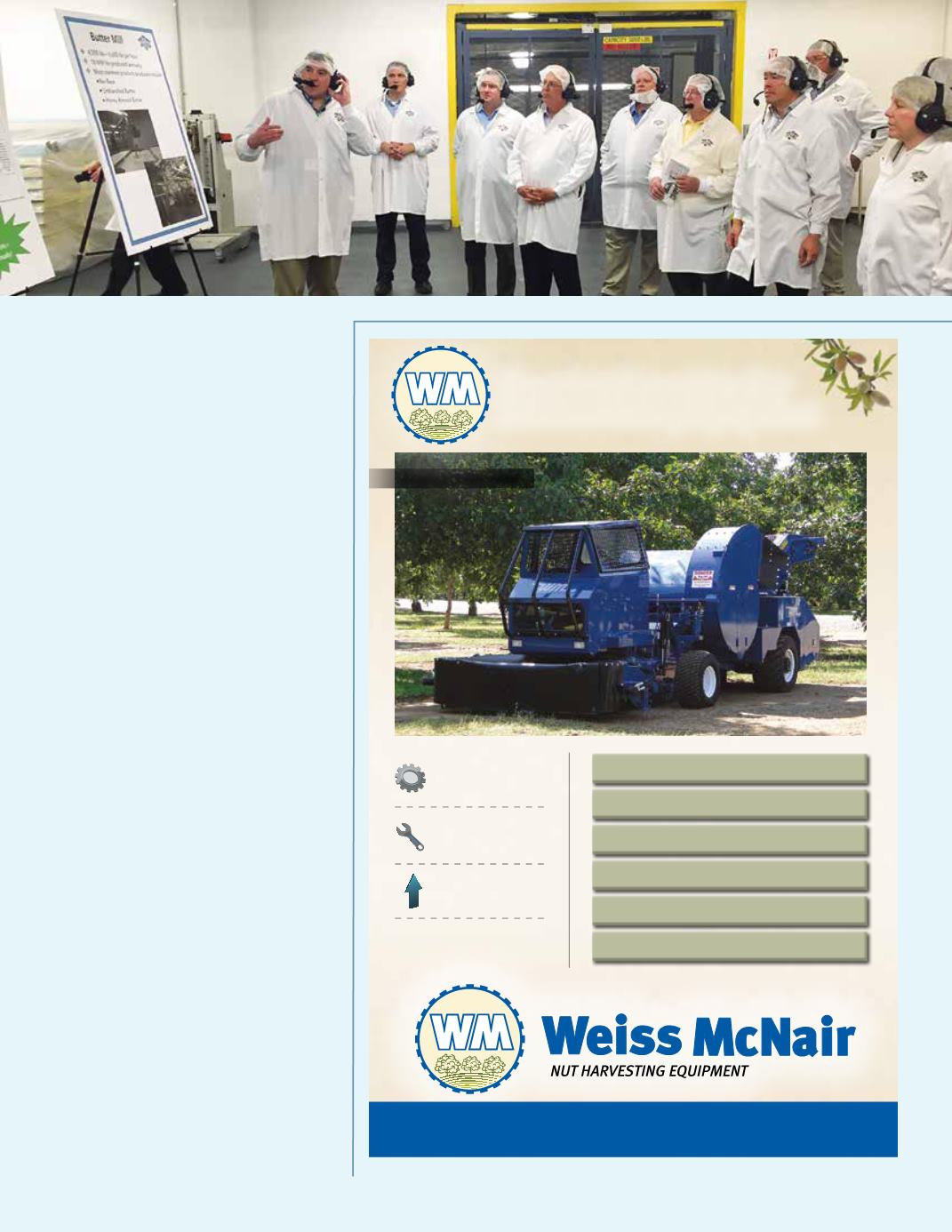

“Our team was pleased to show great

progress with improvements in safety,

quality, yield and throughput, as well

as the volume of work we do here in

Sacramento to deliver the benefits of

almonds to the world!” Hatfield said.

WM-AlmondFacts1/2v.indd 1

8/28/13 5:44 AM